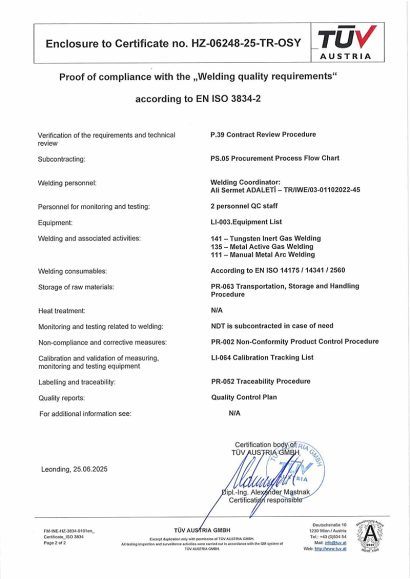

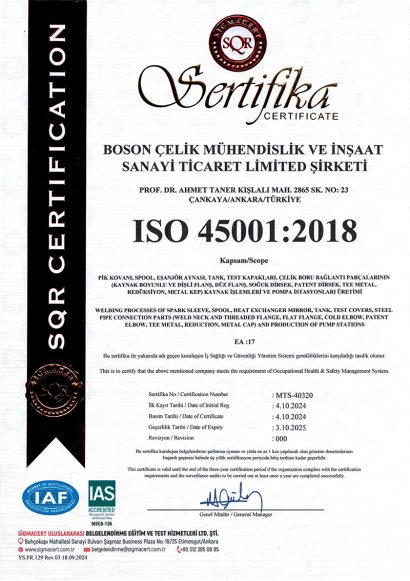

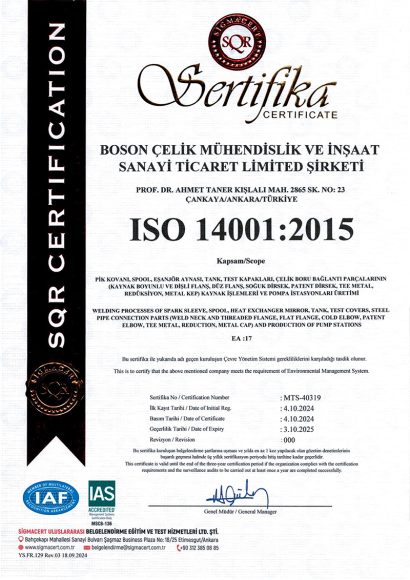

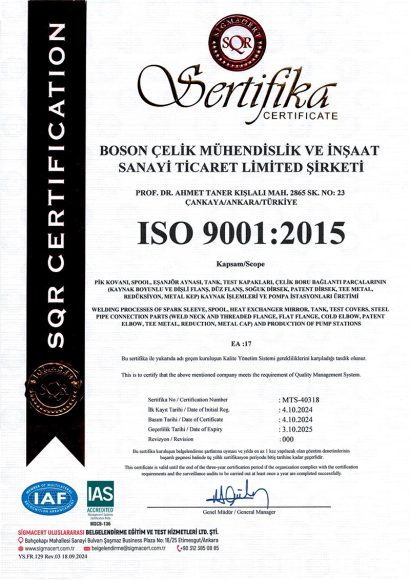

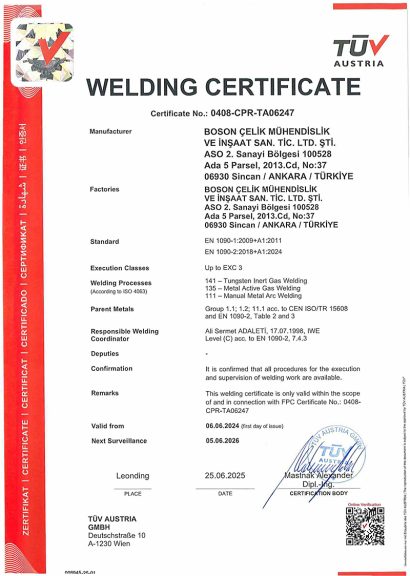

Our company possesses all the necessary quality certificates to ensure that our production meets international standards. We implement a systematic and controlled approach to all business processes through the ISO 9001 Quality Management System, and we certify the quality of our welding operations with the ISO 3834-2 standard. Additionally, we hold compliance certificates for steel structure manufacturing according to EN 1090-2 and for the European Union’s Pressure Equipment Directive PED (2014/68/EU).

In our production processes, we base our work on internationally recognized technical standards such as ASME Section VIII Div.1, EN 13445, AD 2000 Merkblatt, TEMA, and API. For all welded fabrications, project-specific welding procedures (WPS), procedure qualification results (PQR), and welder qualification records (WPQ) are prepared. Welding operations are performed by certified welders according to European (EN ISO 9606-1) or American (ASME IX) standards.

Before delivery, our products undergo comprehensive quality control processes. These include visual inspection of welds (VT), penetrant testing (PT), magnetic particle testing (MT), ultrasonic and radiographic testing (UT and RT), dimensional checks, hydrostatic pressure tests, and surface roughness measurements. All tests are conducted using calibrated and reliable equipment, and the results are documented in detail.

Finally, for each production batch, material certificates (EN 10204 3.1 or 3.2) and all product-specific quality certificates and test reports are provided to our customers. This ensures a transparent and fully traceable production process.